GFRP Rebar | Composite Rebar

What is a GFRP rebar and Why Should You Consider It?

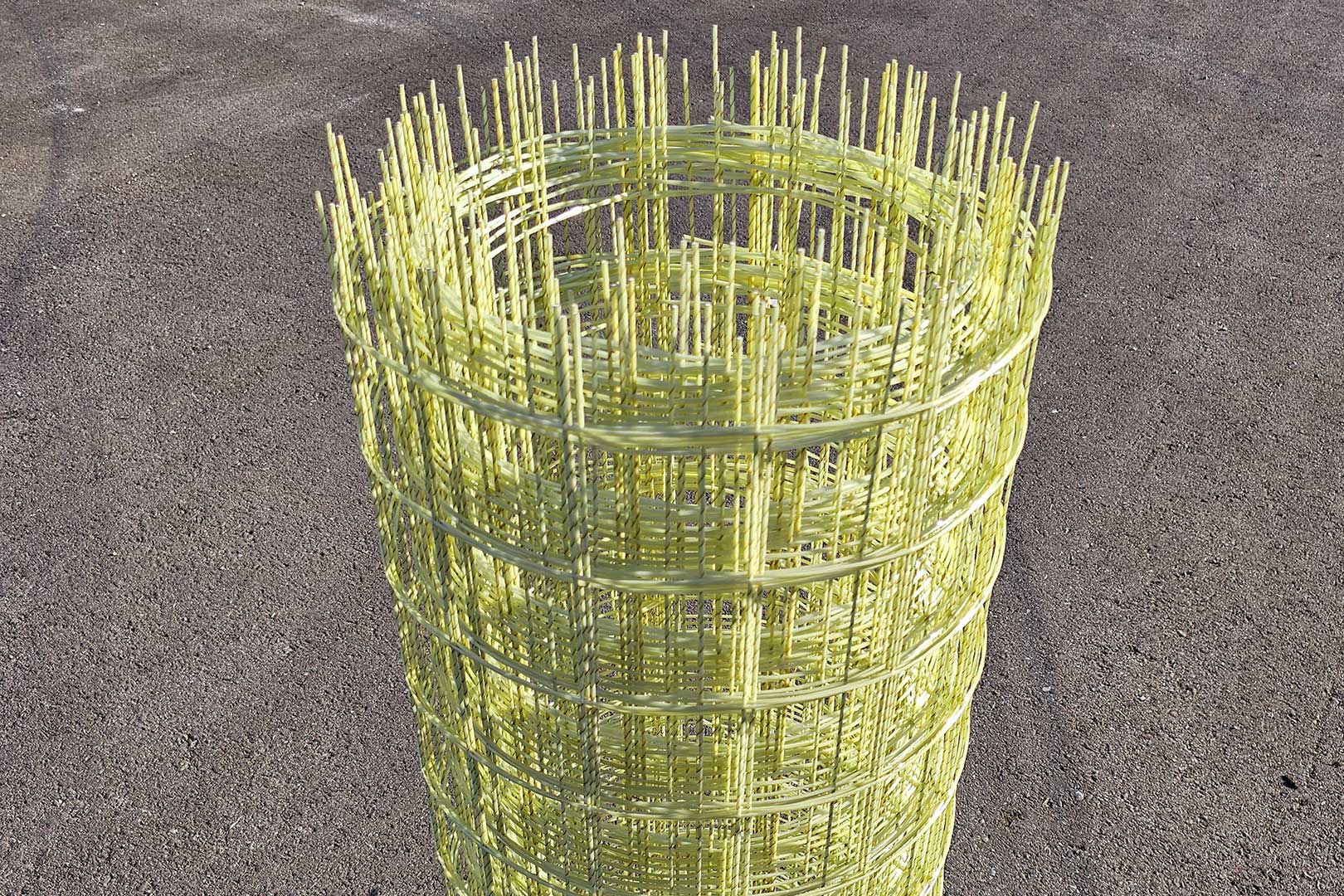

GFRP (Glass Fiber Reinforced Polymer) rebar is an innovative building material that offers a highly efficient alternative to traditional steel reinforcement in concrete structures. Made from multiple strands of fiberglass saturated with a thermo-reactive epoxy resin, GFRP rebar provides exceptional mechanical properties, including high tensile strength and durability. The surface of GFRP rebar is typically designed with a ribbed or spiral pattern, which improves adhesion between the rebar and concrete or bituminous materials, thereby enhancing the overall bond strength and structural integrity.

FRP reinforcement, including GFRP rebar, significantly enhances the durability of structures due to its resistance to corrosion and chemicals. Unlike steel, GFRP does not rust, making it ideal for use in environments where corrosion is a major concern, such as coastal or chemically aggressive environments. Its high tensile strength allows GFRP to handle heavy loads effectively, which is beneficial in projects where reducing the overall weight of the structure is critical. Additionally, GFRP’s non-conductive properties make it suitable for applications that require materials with electrical insulation characteristics, offering an alternative to steel in specific technical applications.

The lightweight nature of GFRP rebar, combined with its low thermal conductivity and resistance to extreme environments, further underscores its advantages over conventional materials. GFRP rebars are available in standard lengths as well as coils up to 300 meters, reducing transportation and installation costs due to their ease of handling. The use of GFRP in construction projects can also shorten the construction period and extend the lifespan of structures because of its corrosion resistance and long-term durability.

Our high-quality GFRP rebars are manufactured using automated processes and cutting-edge technology. As producers, we maintain competitive prices and superior quality by sourcing raw materials from trusted European suppliers and adhering to the latest European Union regulations.

OUR GFRP REBAR IN NUMBERS

Geometry and structure

Bar diameter

6 mm – 12 mm

Density

2.2 g/cm³

Tensile Strength

≥ 1100 MPa

8 mm rebar weight

0.112 kg/m

Type of packaging

Standard Length Coils

50m, 100m

Standard Length Bars

3m, 6m, other – on request

Standard Coil Size

800mm, 1000mm, 1300mm

Meters Per Pallet (coils)

Up to 8500m

Bars Per Pack

Up to 500pcs

Reliability confirmed by certificates

Certification

EAD 260023-00-0301

Certification

ISO 9001

CERTIFICATION

EPD-Kiwa-EE-000447-EN

OUR OTHER PRODUCTS

REBARMAT® FRP mesh is an innovative alternative to traditional A/B class steel construction mesh, offering enhanced properties and performance.

REBARMAT® Mesh System features large 2.3m x 6m sheets made from welded GFRP rebars. It offers exceptional strength, along with superior durability and corrosion resistance.

ROUND Rebars are designed for the light precast industry and specialized applications. These GFRP rebars provide excellent strength, corrosion resistance, and lightweight handling, making them ideal for precision projects.

UV Rebars are engineered for use in sun-exposed environments, such as agricultural and outdoor structures. With enhanced UV resistance, they offer lasting durability and reliable performance under prolonged sunlight.

UV Mesh is ideal for sun-exposed applications, including green wall facades that support plant growth. Its UV resistance ensures long-lasting durability and reliable performance in outdoor environments.