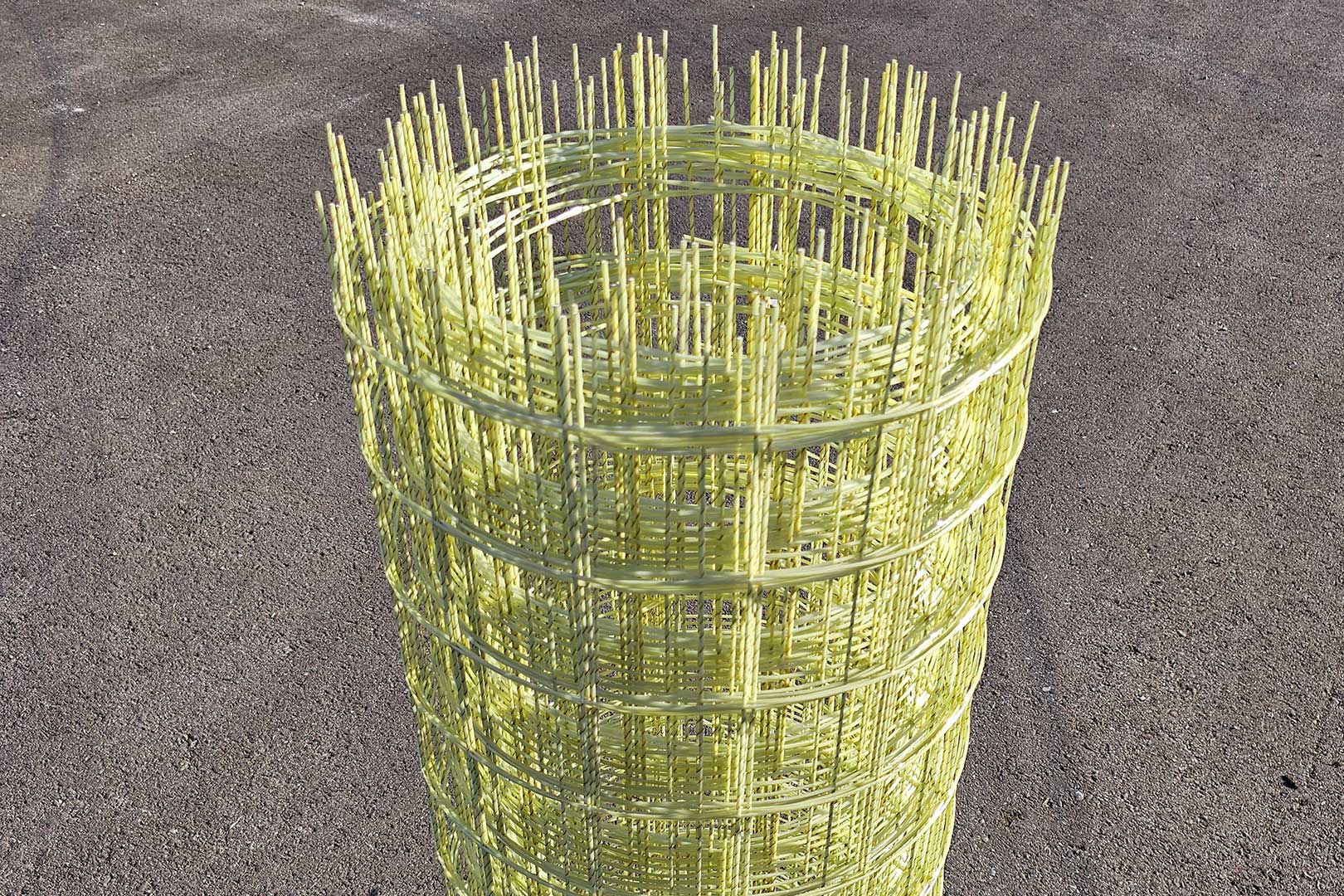

GFRP Mesh

Glass Fiber Reinforced Polymer (GFRP) mesh is a lightweight yet sturdy reinforcement solution, offering significant advantages over traditional steel in various construction applications. Engineered from glass fibers, this advanced material delivers superior performance while being significantly easier to handle and install.

GFRP mesh’s lightweight nature accelerates installation, making construction more efficient. Its corrosion resistance means it won’t rust, providing a lifespan of up to 80 years and reducing the need for ongoing maintenance. Additionally, its non-conductive properties make it ideal for projects where electrical insulation is critical.

From reinforcing concrete structures to enhancing thermal insulation and supporting facades, GFRP mesh offers exceptional strength and longevity. It’s an optimal choice for demanding projects in a range of environments. Moreover, the mesh can be customized to meet specific project requirements, offering a versatile and precise solution for a variety of construction needs.

OUR COMPOSITE MESH IN NUMBER

Geometry and structure

Thickness

from 2 mm to 6 mm

Mesh

5 cm, 10 cm, 15 cm, 20 cm

Width

up to 1 m

Length

up to 50 m

Type of packaging

Packed in coils

from 1 m to 12 m

Reliability confirmed by certificates

Certification

ISO 9001

Applications of FRP Mesh

Glass Fiber Reinforced Polymer (GFRP) mesh is gaining popularity across various sectors due to its high strength-to-weight ratio, corrosion resistance, and extended service life. This material is especially beneficial in the following areas:

- Water Treatment Facilities:

GFRP is ideal for sewage and water treatment plants, where exposure to harsh chemicals is common. Its chemical resistance ensures long-term performance, reducing maintenance costs. - Road and Highway Construction:

GFRP mesh is widely used in pavements, overlays, and barriers, offering a lightweight and durable alternative to steel reinforcement. Its resistance to weathering and de-icing salts helps reduce upkeep and extend the lifespan of road infrastructure. - Marine Structures:

Due to its excellent resistance to saltwater, GFRP mesh is a reliable solution for docks, seawalls, and other coastal infrastructure, significantly enhancing their durability and lifespan. - Parking Garages and Elevated Structures:

In areas where weight reduction and environmental durability are crucial, GFRP mesh provides an effective reinforcement solution, offering long-lasting performance in challenging conditions. - Industrial Flooring:

GFRP mesh is highly durable and resistant to chemical spills, making it suitable for use in industrial environments with heavy machinery and chemical exposure. - Rail Infrastructure:

The material is often used in rail platforms, crossings, and tunnels due to its durability, corrosion resistance, and ability to withstand heavy loads and environmental factors. - Airport Runways and Aprons:

GFRP mesh is capable of bearing heavy loads while resisting chemicals and weathering, making it an ideal choice for reinforcing airport infrastructure, including runways and aprons. - Architectural Applications:

The flexibility of GFRP mesh allows architects to explore creative and complex designs without compromising structural integrity, offering both aesthetic and functional advantages.

FAQ – GFRP Mesh | Rebarmat

Why Choose Composite Mesh Over Traditional Steel Mesh?

Is the Fiberglass Mesh Resistant to Corrosion?

How is GFRP Mesh Transported and Installed?

What Key Properties Should I Look for in GFRP Mesh?

• Corrosion Resistance: Ensures durability in harsh environments like coastal regions or chemical-exposed areas.

• High Tensile Strength: Provides strong support for concrete reinforcement, improving structural integrity.

• Flexibility: Makes handling and installation easier, reducing labor time and costs.

• Durability: Extends the service life of the structure, minimizing maintenance needs and long-term costs.

Common Mistakes to Avoid When Working with GFRP Mesh

• Improper Storage: Ensure mesh is stored properly to prevent UV degradation.

• Incorrect Cutting Tools: Use the right tools to avoid damaging the fibers.

• Overlooking Overlap Requirements: Follow specified overlap lengths for structural integrity.

• Ignoring Thermal Expansion Differences: Account for GFRP's different thermal expansion rates compared to concrete during installation.

OUR OTHER PRODUCTS

FRP REBARMAT® PRO Rebars exhibit exceptional physical and mechanical properties, with a strength that is two times greater than that of B class steel rebar

REBARMAT® Mesh System features large 2.3m x 6m sheets made from welded GFRP rebars. It offers exceptional strength, along with superior durability and corrosion resistance.

ROUND Rebars are designed for the light precast industry and specialized applications. These GFRP rebars provide excellent strength, corrosion resistance, and lightweight handling, making them ideal for precision projects.

UV Rebars are engineered for use in sun-exposed environments, such as agricultural and outdoor structures. With enhanced UV resistance, they offer lasting durability and reliable performance under prolonged sunlight.

UV Mesh is ideal for sun-exposed applications, including green wall facades that support plant growth. Its UV resistance ensures long-lasting durability and reliable performance in outdoor environments.