REBARMAT® GFRP Reinforcement for Precast Tram Rail Elements

PRODUCT

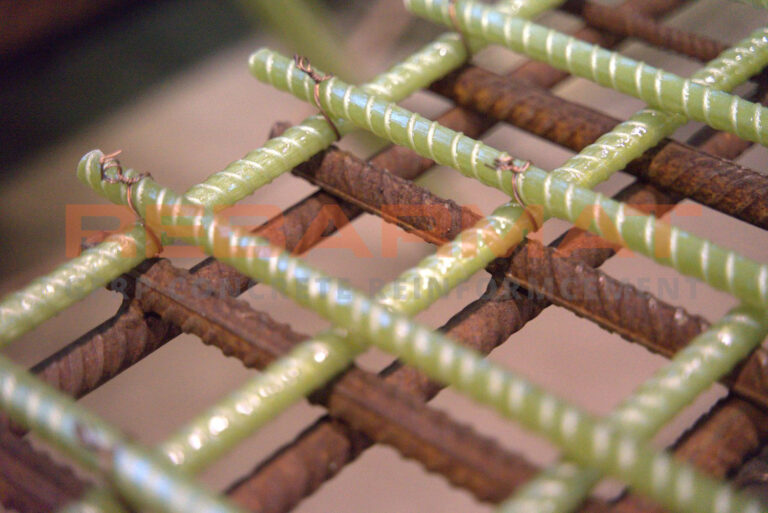

REBARMAT® GFRP PRO rebars

– Non-metallic, corrosion-resistant glass-fiber reinforced polymer reinforcement

Dimensions

Bars

Bar diameter: Ø16 mm, Ø12 mm, Ø8 mm

Format: Supplied according to specification

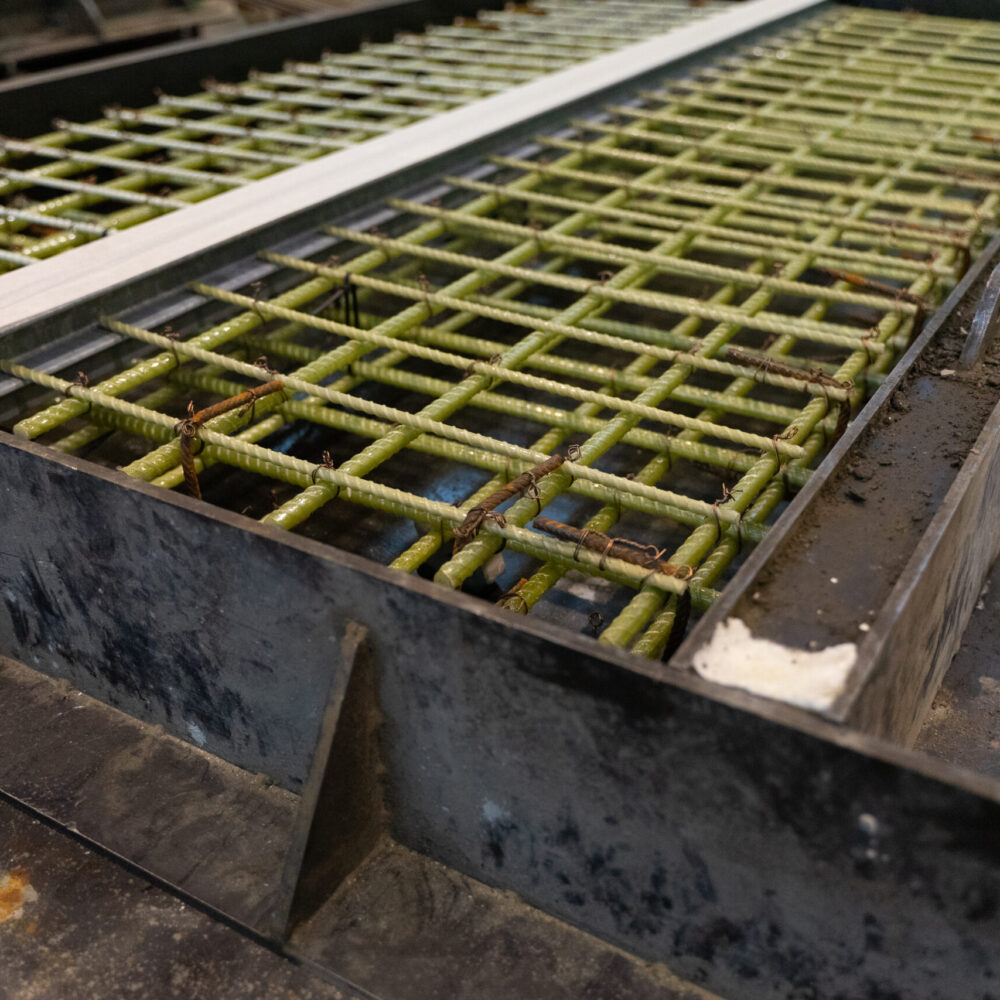

Integrated into factory-controlled precast moulds

Location

Latvia

Infrastructure & Transport

Used for

– Precast concrete slabs for tram and light rail tracks

– Embedded rail-support elements

– Urban transport infrastructure components

– Track slabs exposed to moisture, vibration and de-icing salts

Installation

– Installed directly in precast moulds before concreting

– Maintains precise cover and geometry during casting

– Fully compatible with standard precast production workflows

Why GFRP instead of steel

No corrosion – Fully resistant to water, chlorides and de-icing salts common in tram corridors.

Extended service life – Eliminates corrosion-driven cracking and spalling in precast track elements.

Lightweight handling in precast plants – Easier mould placement, reduced manual handling and faster assembly.

Electromagnetic neutrality – No interference with signalling, sensors or control systems.

Stable performance under vibration – Suitable for cyclic loads and long-term operational stress.

Key advantages

– Longer lifecycle of tram track slabs

– Reduced maintenance and replacement costs

– Improved durability in urban exposure classes

– Faster production and easier handling

– Predictable, repeatable quality in factory conditions

Reference standards

EN 1992-1-1 (Eurocode 2, Annex R)

Concrete design principles (applied by analogy)

CNR-DT 203 R1 (2026)

Guide for the design and construction of concrete structures reinforced with FRP bars

EN 206 Concrete exposure classes for transport infrastructure

EN 13232 (series) Railway applications – Track – Special trackwork (application context)

EAD-based GFRP reinforcement principles

Sustainability

– Long service life

– Reduced maintenance

– Corrosion-free lifecycle

Product

FRP REBARMAT® PRO Rebars exhibit exceptional physical and mechanical properties, with a strength that is two times greater than that of B class steel rebar

Gallery